Innovation Fasteners is a manufacturer and distributor of high-performance precision fasteners and machined components.

Used in the Oil & Gas Industry within Military & Marine in Power Generation within Waterworks Industry within Renewable Energy to support the Mining Industry

Innovation Fasteners is a manufacturer and distributor of high-performance precision fasteners and machined components.

Used in the Oil & Gas Industry within Military & Marine in Power Generation within Waterworks Industry within Renewable Energy to support the Mining Industry

STUDBOLT

DOUBLE END STUDS

HEXAGON NUTS

HEX HEAD BOLTS

SOCKET CAP SCREWS

12 POINT BOLT

SOCKET SET SCREWS

UBOLTS

WASHERS

STAY ROD

Everything you need

Services & Solutions

QUALITY ASSURANCE

Quality of product and service is driven throughout the company by Innovation Fasteners’ ISO 9001:2015 approved management system. Our commitment to product quality and customer satisfaction ensures that our products are supplied right first time.

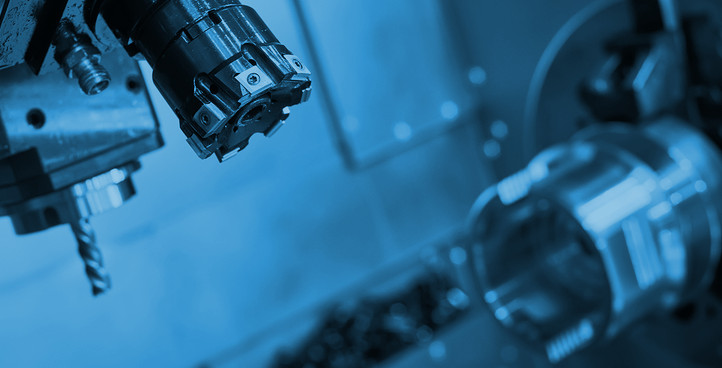

IN HOUSE MACHINE SHOP

Innovation Fasteners boasts substantial in house manufacturing capabilities which include CNC lathes and mills among other specialist fastener manufacturing equipment. This control allows for expedited lead times and a 24 hours a day, seven days a week hot shot service.

TIMELY SOLUTIONS

We understand that time is of the essence in the energy industries and that down time can often cost thousands of dollars, so we ensure that we are always able to provide a timely solution to meet your needs. If you have a breakdown or an emergency situation, we’re always available for a hot shot service which operates 24 hours a day, 7 days per week.

CUSTOMER FOCUSED

Innovation Fasteners believes in working with our customers to build partnerships which leads to increased customer service. We build relationships to gain a better understanding of what our customer expect and require from us to make sure that every transaction is as smooth as possible for both companies.

What we do

Manufacturing Capabilities

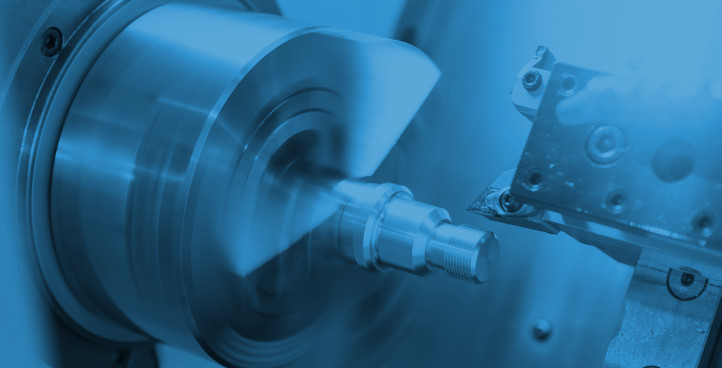

CNC TURNING

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix tool path by moving more or less linearly while the work piece rotates.

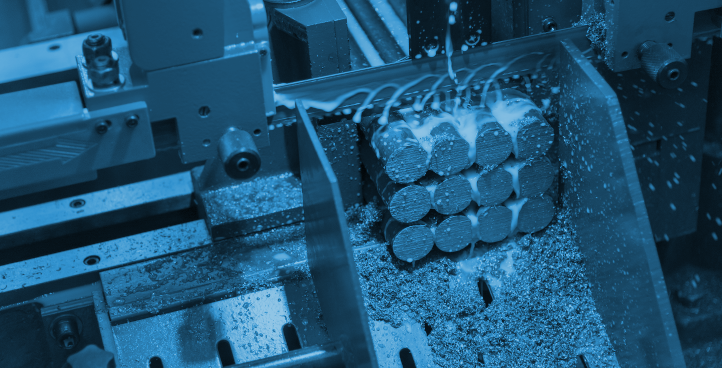

AUTOMATIC BAND SAWING

Automatic band saws feature preset feed rate, part feeding, and part clamping. They are used in production environments where having a machine operator per saw is not practical. Automatic saws rely on numerical control to not only cut faster, but to be more precise and perform more complex cuts.

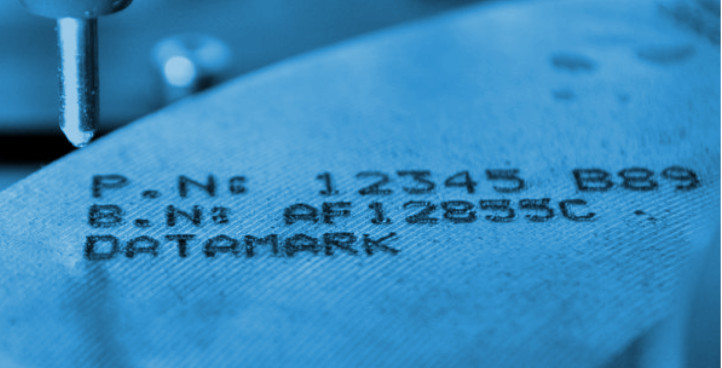

DOT PIN MARKING

Dot peen marking technology allows us to automate the direct part marking process, ensuring 100% reliable part traceability. Dot peen marking systems give us the ability to place high quality marks on your products consistently and quickly.

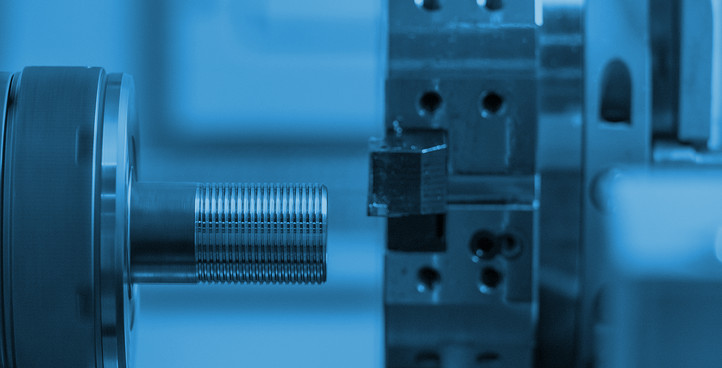

THREAD ROLLING

A process where threads are formed by moving material instead of cutting away material. Dies have a mirror image of the thread form ground into them. The part is rotated and pushed into the die causing the material to flow into the die, forming the thread. Cold working of the material makes the threads stronger.

CNC MILLING

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. It is one of the most commonly used processes for machining custom parts to precise tolerances.

THREAD CUTTING

Single-point threading is an operation that uses a single-point tool to produce a thread form on a cylinder or cone. The tool moves linearly while the precise rotation of the work piece determines the lead of the thread.

Our Products

HEXAGON NUTS

STUDBOLT

HEX HEAD BOLTS

DOUBLE END STUDS

SOCKET CAP SCREWS

12 POINT BOLT

SOCKET SET SCREWS

STAY ROD

UBOLTS

WASHERS

Our Project Gallery

Recent Projects

2 1/4″ 8UN X 22″ STUDBOLT 2 HEAVY HEX NUTS ASTM A193 B8C / A194 8C

Innovation Fasteners were called upon for a 5 day delivery to support an unplanned maintenance project for an oil refinery in Texas. The order was

1 1/16″ 16 UN-2A MACHINED COMPONENT ASTM A582 416 CONDITION T

We machined a threaded component that needed to be expedited for a power generation application. The parts were turned and milled on our Doosan GT2100M from

LOW HEAD SOCKET CAP SCREWS – ASTM A564 17-4 H1150D

Low Head Socket Cap Screws machined from ASTM A574 17-4 H1150D material. Innovation Fasteners worked around the clock to ensure our customers’ production lines could

The best

Experience Team

Innovation Fasteners management team has over 100 years of experience between them!

Daniel Fellows

Co-Founder - Innovation Fasteners

Jorge Torres

Co-Founder - Innovation Fasteners

Julio Parra

Co-Founder - Innovation Fasteners

Hugo Rodriguez

Sales - Innovation Fasteners

What's new

Recent News

DOOSAN LYNX 220LSY Y AXIS CNC

We added a bar-fed Doosan Lynx 220 Y-axis horizontal single turret lathe to our collection. The Lynx 220LSY lathe has been extended to include a

INCREASED SAW CAPACITY

Innovation Fasteners have increased their automatic band saw capacity to keep up with customer demands. As we see the business grow, we are proactively investing

2 NEW DOOSAN GT2100M CNC’S

Innovation Fasteners recently invested in 2 new 3-axis Puma GT2100M CNC machines! These new machines, capable of machining 90% of our products, will increase our