Manufacturing Videos

What we do

Manufacturing Capabilities

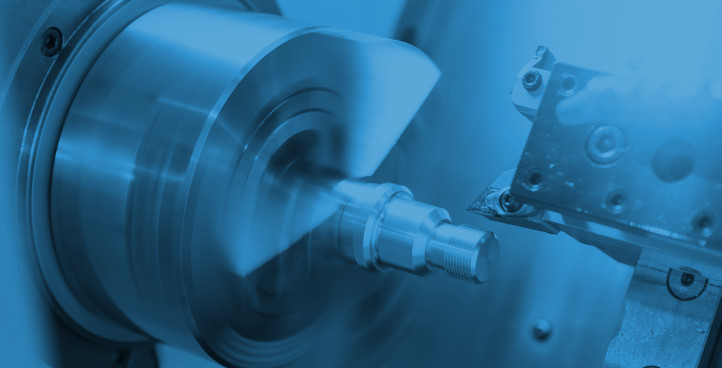

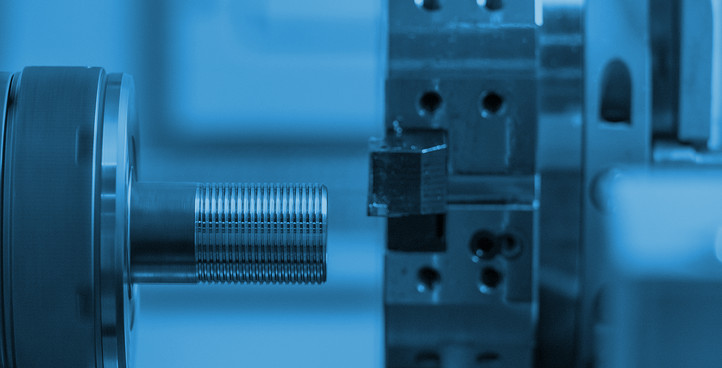

CNC TURNING

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix tool path by moving more or less linearly while the work piece rotates.

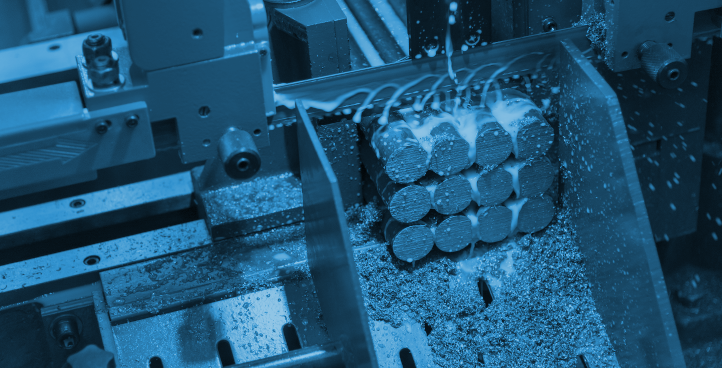

AUTOMATIC BAND SAWING

Automatic band saws feature preset feed rate, part feeding, and part clamping. They are used in production environments where having a machine operator per saw is not practical. Automatic saws rely on numerical control to not only cut faster, but to be more precise and perform more complex cuts.

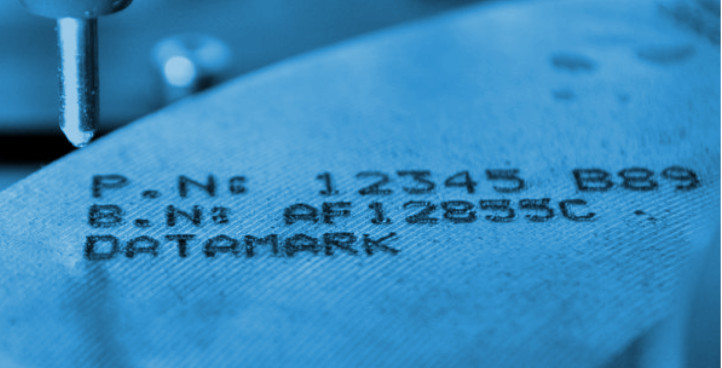

DOT PIN MARKING

Dot peen marking technology allows us to automate the direct part marking process, ensuring 100% reliable part traceability. Dot peen marking systems give us the ability to place high quality marks on your products consistently and quickly.

THREAD ROLLING

A process where threads are formed by moving material instead of cutting away material. Dies have a mirror image of the thread form ground into them. The part is rotated and pushed into the die causing the material to flow into the die, forming the thread. Cold working of the material makes the threads stronger.

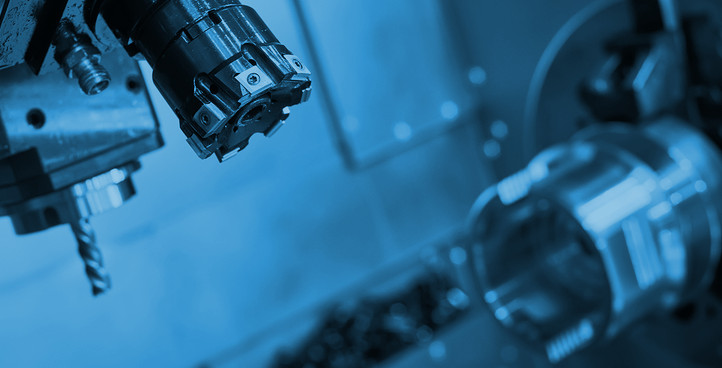

CNC MILLING

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. It is one of the most commonly used processes for machining custom parts to precise tolerances.

THREAD CUTTING

Single-point threading is an operation that uses a single-point tool to produce a thread form on a cylinder or cone. The tool moves linearly while the precise rotation of the work piece determines the lead of the thread.